INDUSTRIAL AND ENVIRONMENTAL SAFETY

Project’s Aim – assurance of reduction of risks of the oil and gas business and prevention of environmental damage.

Main directions of the project:

Industrial safety expertise;

Providing environmental safety;

Industrial construction.

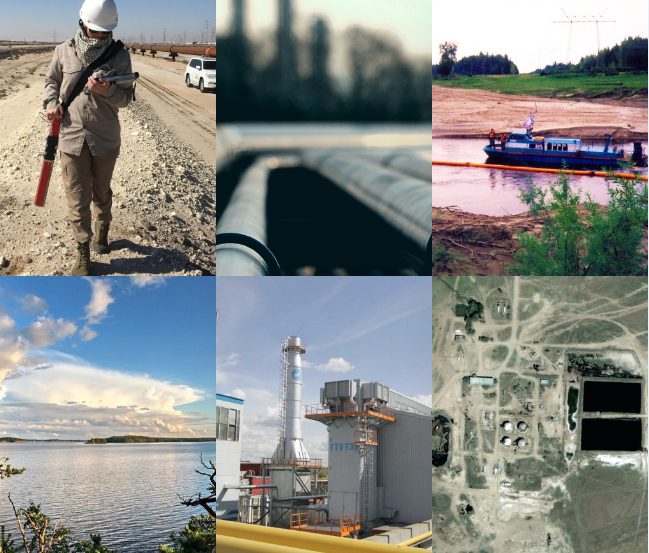

The project has accumulated a wealth of experience in the inspection of industrial pipelines and reservoirs, remediation and decontamination of oil-contaminated soils and reservoirs, as well as the construction of sites for the disposal of industrial waste.

-Hardware-software magnetometric diagnostic

-Industrial safety expertise

-Remediation of soil

-Decontamination of surface and ground waters

-Cleaning tanks and sludge pits

-Development of environmental documentation

INDUSTRIAL SAFETY

Non-Contact Magnetometric Inspection

ADVANTAGES:

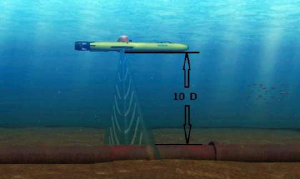

Remote (up to 10 diameters of the pipe) diagnostics of pipelines state;

No stop or disruption of the flow is required;

Detects anomalies real-time;

High speed – 5-10 km a day;

Reliability for severe flaw detection reaches 93 %;

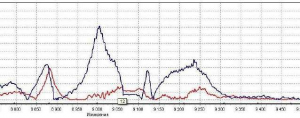

Digital mapping with GPS coordinates of anomalies, object’s automatic routing;

Inspection of non-piggable sections;

The use of artificial intelligence technologies in data processing.

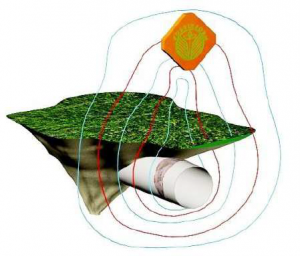

TECHNOLOGY

Hardware-software magnetometric diagnostic complex of “KMD” series:

Using Villari Effect (magnetostrictive effect) KMD devices

detect changes in the pipelines’ magnetic field caused by various

flaws (incl. stress, tension, corrosion, etc.):

-From the surface or under water, up to 10 diameters of the pipe;

-An additional electrometric channel allows to evaluate state of insulation of underground pipelines;

-The received data is recorded in the memory of the field computer and visualized in the form of magnetograms showing the location of anomalies with links to a digital map and coordinates.

DETECTABLE DEFECTS

-Stress-deformed state – SDS; Corrosion fatigue;

-Defects related to loss of metal and failure of metal’s solidity (except pinhole corrosion);

-Change of the pipeline’s geometry;

-Unauthorized inserts.

IN THE FRAMEWORK OF HARDWARE-SOFTWARE MAGNETOMETRIC COMPLEX OF GROUND AND UNDERGROUND PIPELINES, IT IS POSSIBLE TO INSTALL THE DIAGNOSTIC EQUIPMENT ON UAVs (drones)

Economic Benefits of installing diagnostic devices on

UAVs (drones):

-High speed of inspection;

-Impact of the human factor minimization;

-Organization of regular monitoring of objects;

-The possibility of continuous diagnosis of hard-to-reach areas (swamps, deserts);

-Creation of a digital model of a pipeline (“digital duplicate”), reflecting complex data of the object, obtained through different channels (magnetic, thermal imaging, visual, etc.).

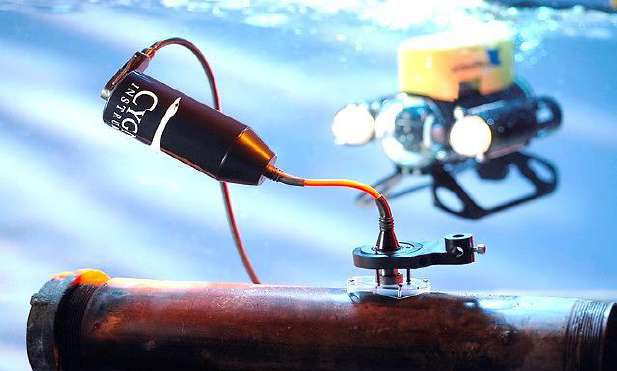

ROV (Remotely Operated Underwater Vehicle) is used for non-contact magnetometric inspection of underwater pipelines

ROV is operated while the inspection and received magnetometric data is recorded in real time for further analysis.

ENVIRONMENTAL SAFETY

-Soil remediation;

-Liquidation of accidental oil products spills;

-Decontamination of surface and ground waters of oil products spills;

-Hazardous waste management.

SOILEX® biopreparation is used for soil and water remediation and recultivation, based on the usage of specific microorganisms-destructors for decontamination of surface and ground waters of oil products spills.

Advantages of the technology:

-Adaptability to specific needs;

-High destructive activity of wide range pH (4,5-8,5), maintained within a wide range of temperatures (3 – 45 °С);

-Decontamination in short time (3-8 months);

-The strains retain high viability and oil oxidizing activity;

-Effective against a wide range of pollutants, including heavy metals and nitrates;

-Full rehabilitation of the ecosystem at the contaminated territory.

SOILEX® biopreparation usage examples

Before/After

INDUSTRIAL CONSTRUCTION

-Design and construction of sites for waste processing;

-Design, construction and maintenance of treatment facilities.

EXPERIENCE: CONSTRUCTION OF SITES

Construction of the site for processing 30 000 m3 of the oil sludge, square over 3,5 ha.

Construction of the road connecting highway with the site

Constructing the site’s sectors, waterproofing

CONSTRUCTION OF SEWAGE TREATMENT PLANTS

Domestic sewage treatment

-Traditional treatment of sewage steps applied –

mechanical and biological;

-The after purification is carried out by means of electrochemical and ultraviolet irradiation, which leads to stabilization of purified water characteristics during all operation life of equipment;

-The treatment of sewage from the polluted areas is possible to be reused or thrown into a pond;

-Electrochemical purification and filtration technologies are used without the use of reagents;

-The technique can be used in complex treatment systems as the system of after-purification.

Industrial sewage treatment

Domestic sewage treatment:

-Traditional mechanical and biological treatment;

-Post-treatment by ultraviolet irradiation.

Industrial sewage :

-Design and construction of local treatment facilities;

-Overhaul of treatment facilities;

-Organization of circulating water supply.

Rain and snow water:

-Electrochemical purification and filtration technologies without the use of reagents;

-Water can be reused or thrown into a pond;

-No need in the expensive consumables.

Equipment

Main principles of all equipment operating:

-Using the reverse water supplying;

-Easy and safe exploitation;

-Does not need permanent maintenance staff;

-Low power consumption and operating costs;

-No chemical reagents.

The technology of the reverse water supplying

allows lowing water consumption up to 90%,

installation at the sites not equipped with a drainage

system and water nets.