Solliance develops a perovskite solar cell with 93 % average near infrared transparency. ECN shows 26.3% tandem cell efficiency when combining the perovskite solar cell with its 6 inch industrially processed c-Si cell.

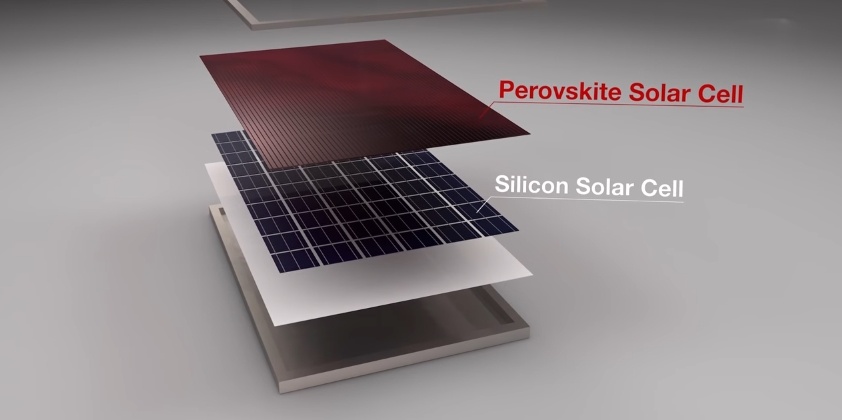

On March 19th, 2018, at the Silicon PV/nPV conference, in Lausanne, Switzerland, Solliance announces that it has achieved a major milestone in perovskite technology for application in future industrial high efficiency tandem photovoltaic cells and modules by realizing a perovskite cell that combines good cell efficiency with a very high near infrared transparency of 93%. Also at the conference, ECN shows that when this perovskite cell is mechanically stacked on a 6 inch2 silicon bottom cell with its proprietary MWT-SHJ (metal-wrap-through silicon heterojunction) design, 26.3% efficiency is achieved, an increase of 3.6 percentage points over the efficiency of the directly illuminated silicon cell laminate.

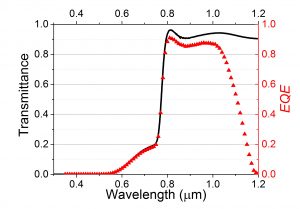

Transmittance curve of the semi-transparent perovskite cell (black line) and the measured external

quantum efficiency of the c-Si cell (red circles) when filtered by the semi-transparent perovskite cell.

Dong Zhang, researcher at Solliance, about the perovskite cell: “By optimizing the ITO (indium tin oxide) composition and deposition conditions as well as careful design of the anti-reflection coating (ARC), an extremely high transparency is achieved for the top electrode, despite the low temperature process window.” Using this ITO, with a sheet resistance as low as 40 Ohm per square, a perovskite photovoltaic cell was made with an average transmittance in the relevant near infrared wavelength range (800 – 1200 nm) of 93 %. This is significantly higher than the state of the art, which is below 85 %. To put this into perspective, the same glass sheet without ARC but with perovskite cell has a transparency in this wavelength range of around 92%.

“The active area of the tested small semi-transparent perovskite cell is 0.09 cm2; the power conversion efficiency is 16.4 %. The performance measurement of the four terminal hybrid tandem was according to the generally accepted procedure as described by J. Werner (J. Werner et al. ACS Energy Letters, vol. 1, pp. 474, 2016). Scaling up from a laboratory scale to an industrial process is one major barrier for a successful implementation of a new promising development. Therefore Solliance employs different scales in development. Now that the device was proven with spin coated layers, we use pilot scale equipment provided by our industrial partners to scale it to a viable industrial production process,” adds Sjoerd Veenstra, program manager Perovskite Solar Cells at Solliance. “Also the expertise of industrial partners of Solliance in sheet-to-sheet spatial ALD and laser interconnection of thin film cells is used to scale-up the technology to 30×30 cm2 demonstration modules.”

The semi-transparent top cell was combined with a 6 inch2 size MWT-SHJ c-Si cell of 22.7% encapsulated cell efficiency, processed by Choshu Industry Co, Ltd., in collaboration with ECN. This bottom cell contributes 9.9 percentage points to the tandem cell efficiency. Bart Geerligs, program manager hybrid tandem solar cells and modules, and Gianluca Coletti, Director of ECN Industry Research Program, at ECN comment:

“This result shows how feasible it is to achieve significant efficiency gain even over high-end crystalline silicon technology and based on industrial process technology. At ECN we are working to further optimize the bottom cells and the module integration to obtain higher conversion efficiency, reliability, and lower production cost to match the market requirements for tandem applications.”

Story Source:

Materials provided by solliance.eu